Simple Troubleshooting Guide for Mini Excavators

Share

URBEXIA CONSTRUCTION: Simple Guide for Mini Excavators

Mini excavators are indispensable in construction, landscaping, and small-scale earthmoving. At URBEXIA CONSTRUCTION, we understand that even the best machines can face minor issues after prolonged use. Quick identification and resolution of these problems can prevent costly downtime and maintain productivity. This guide covers the most common troubleshooting scenarios for mini excavators and practical steps to fix them.

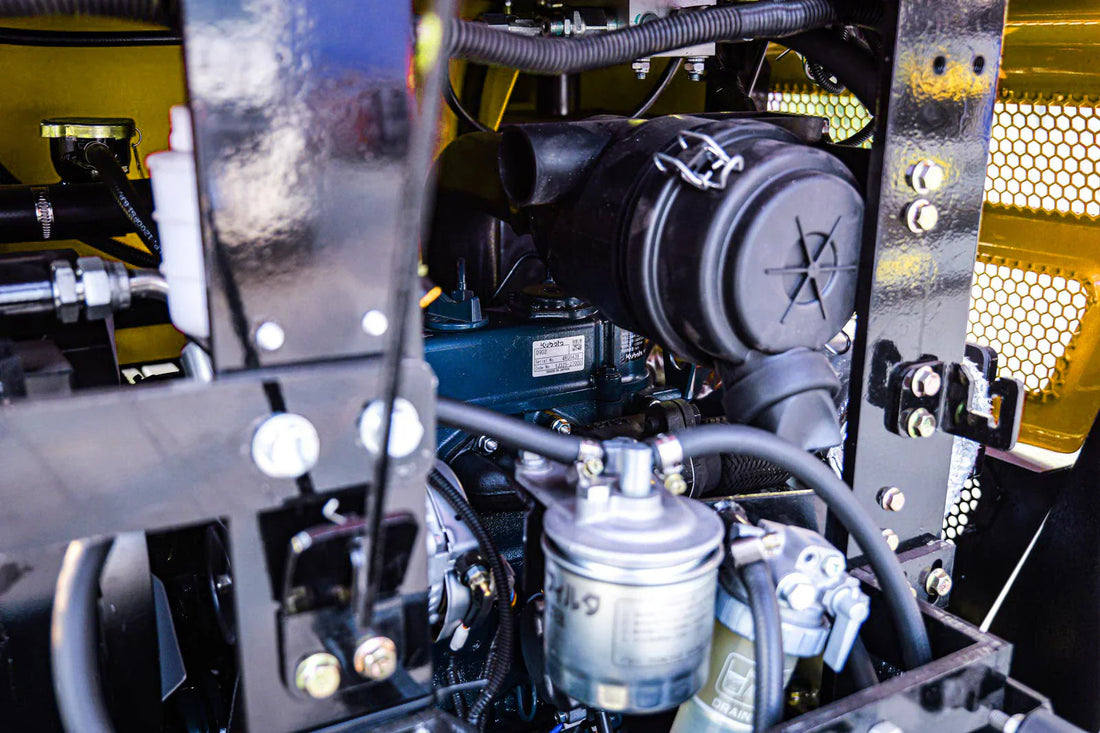

1. Difficult Engine Start

Common causes include:

- Fuel System: Low fuel, clogged fuel filter, or damaged/leaking fuel lines.

- Electrical System: Low battery charge, faulty starter motor, or damaged spark plugs.

- Air Intake: Clogged air filter or air leaks affecting engine combustion.

Check fuel level, replace clogged filters, inspect for leaks, charge or replace the battery, and clean or replace air filters to restore proper engine starting performance.

2. Insufficient Engine Power

Causes may include poor fuel quality, faulty injectors, clogged air filters, turbocharger malfunction, or restricted exhaust systems. Excessive exhaust backpressure—caused by a damaged catalytic converter or muffler—can also lower engine efficiency. Clean the fuel tank regularly, service injectors, and inspect the intake and exhaust systems for damage or blockages.

3. Hydraulic System Failures

The hydraulic system is the operational core of a mini excavator. Problems can occur due to low, contaminated, or overheated hydraulic oil, pump or motor malfunctions, or defective hydraulic valves. These can cause slow, weak, or completely unresponsive movements. Maintain oil levels, replace filters, and service pumps to keep hydraulic performance optimal.

4. Travel System Issues

Mobility problems often result from loose or damaged tracks, broken track plates, or travel motor/reducer failures. Regularly inspect and tension tracks, and service the travel system components to ensure smooth movement between work areas.

Final Advice

While many mini excavator issues can be resolved with basic checks and maintenance, complex faults should be handled by professional technicians to prevent further damage. At URBEXIA CONSTRUCTION, we recommend regular servicing, following manufacturer operation guidelines, and using high-quality parts to extend equipment life and maintain peak efficiency.

mini excavator troubleshooting, mini excavator maintenance guide, excavator won't start, excavator engine start problem, compact excavator repair tips, URBEXIA CONSTRUCTION mini excavator service, mini excavator hydraulic problems, mini excavator travel system failure, excavator track repair, excavator engine power loss, excavator fuel system repair, mini excavator electrical issues, excavator battery maintenance, Kubota mini excavator troubleshooting, CAT mini excavator repair, Bobcat mini excavator maintenance, JCB mini excavator service tips, Hitachi mini excavator troubleshooting, mini excavator air filter replacement, excavator spark plug problem, compact excavator hydraulic leak, mini excavator pump repair, small excavator motor failure, mini excavator reducer issue, compact excavator muffler damage, mini excavator catalytic converter blockage, excavator exhaust restriction, mini excavator turbocharger fault, excavator injector cleaning, compact excavator fuel quality issue, small digger service checklist, mini excavator oil change, mini excavator filter replacement, mini excavator performance loss, URBEXIA CONSTRUCTION excavator diagnostics, URBEXIA CONSTRUCTION construction equipment repair, URBEXIA CONSTRUCTION mini digger parts, URBEXIA CONSTRUCTION hydraulic service, URBEXIA CONSTRUCTION engine repair, URBEXIA CONSTRUCTION track maintenance, URBEXIA CONSTRUCTION travel motor service, URBEXIA CONSTRUCTION exhaust system repair, URBEXIA CONSTRUCTION intake system cleaning, URBEXIA CONSTRUCTION professional excavator service, URBEXIA CONSTRUCTION small excavator troubleshooting, URBEXIA CONSTRUCTION heavy machinery repair